About Traceability

Tracing Our Palm Oil Products To Their Origins

Traceability in the palm oil industry is defined as the possibility to chronologically trace the palm oil products over the supply chain to all its sources. Achieving traceability to our palm oil sources is the first step to create a more sustainable palm oil industry.

Sustainability Dashboard

Since June 2018, ISF has been publishing our Sustainability Dashboard quarterly to chart progress against our commitments detailed in the Sustainability Policy with the aim towards a fully sustainable palm oil industry. Our Dashboard summarises our direct and indirect suppliers, certifications, certified volumes, sources of origin, and traceability to mills and plantations.

Mill List

Consistent with our Sustainability Dashboard, ISF’s mill lists are published quarterly that include our Crude Palm Oil (CPO) suppliers, Crude Palm Kernel Oil (CPKO) suppliers, and the indirect supplying mills they are sourced from. Our mill lists contain information of the supplying mills that fulfill the minimum requirements of the Traceability to Mill (TTM) following our Traceability Protocol.

Traceability to Mills and Plantations

Traceability to Mills (TTM) requires tracing all palm oil mills and kernel crushers that supply directly to ISF. We have achieved 100% TTM since 2018 and have published our CPO and CPKO mill lists quarterly with the required TTM information:

- Mill name and its parent company name

- Universal Mill List (UML) number

- GPS coordinates

- Mill certification status

- Type of certified volume supplied

Traceability to Plantations (TTP) requires tracing our supplies to sources that supply to our mill level, including constantly changing origins such as smallholder farmers, dealers, collection centres, and owned or third-party estates. We work regularly with our suppliers to collect the required information for TTP and aim to achieve and maintain 100% TTP for both our CPO and CPKO sources.

Our TTM and TTP figures from our Traceability Dashboard are calculated based on the definitions as defined by our Traceability Protocol and have been third-party verified.

ISF’s Q4 (October-December 2025) Traceability Dashboard

Traceability To Mill

Palm Oil

Palm Kernel Oil

Traceability to Plantations

Palm Oil

Palm Kernel Oil

Source of origin

Peninsula Malaysia

East Malaysia

Palm Oil

Palm Kernel Oil

Palm Oil

Palm Kernel Oil

Certified Volume Sourced

Palm oil

- RSPO Certified

- MSPO Certified

- Conventional

Palm Kernel oil

- RSPO Certified

- Conventional

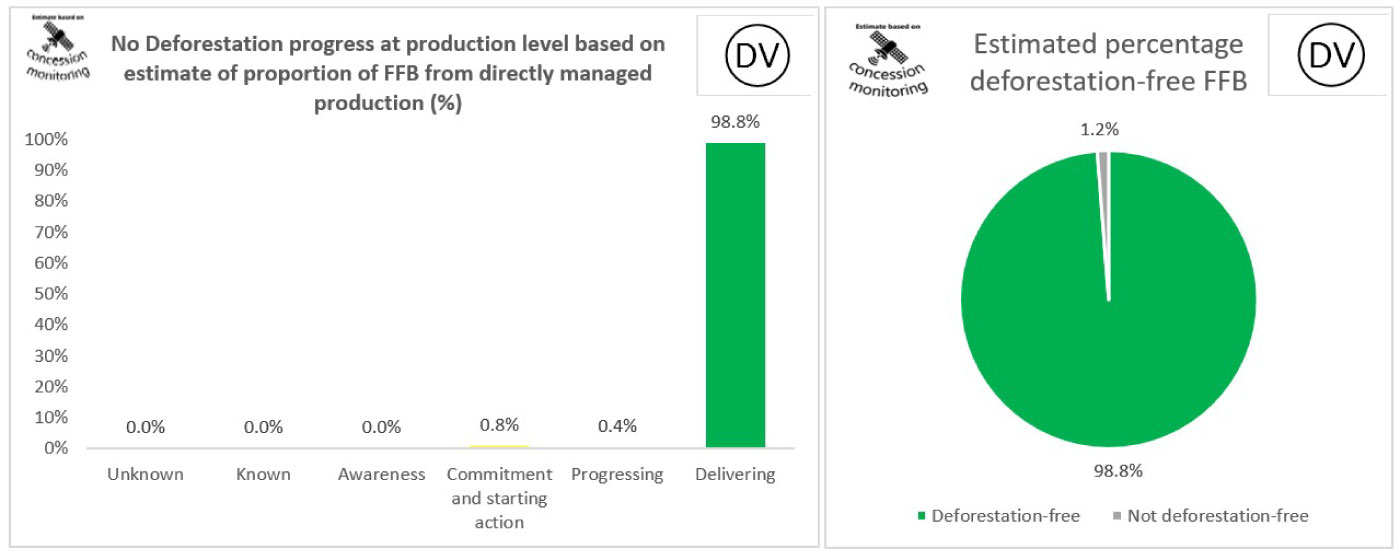

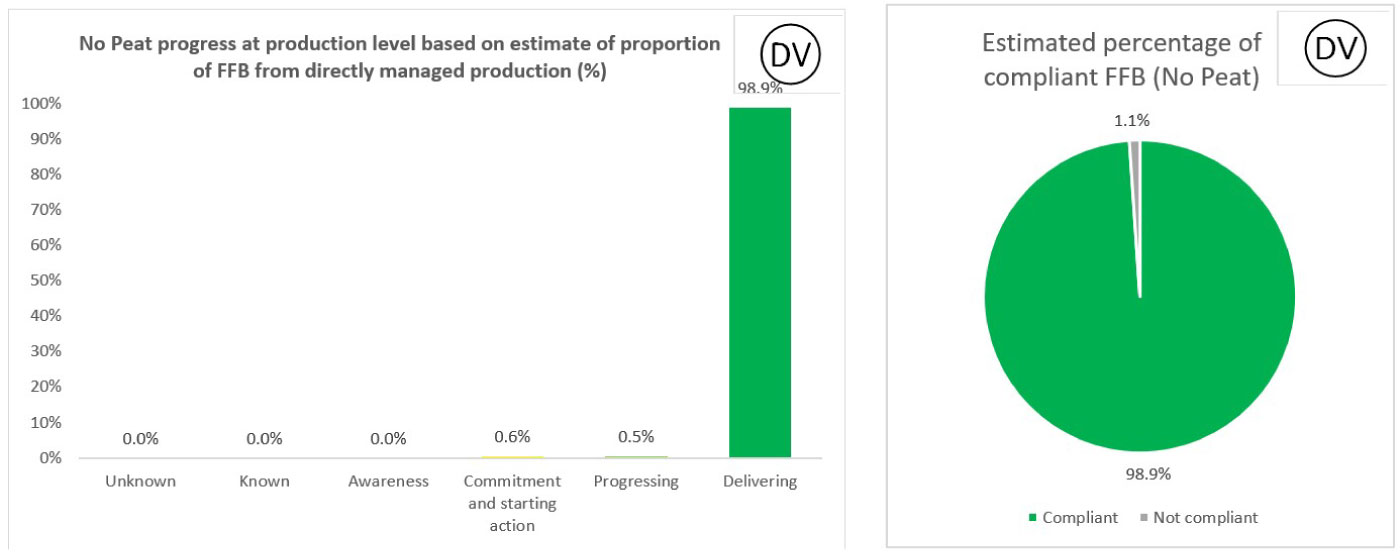

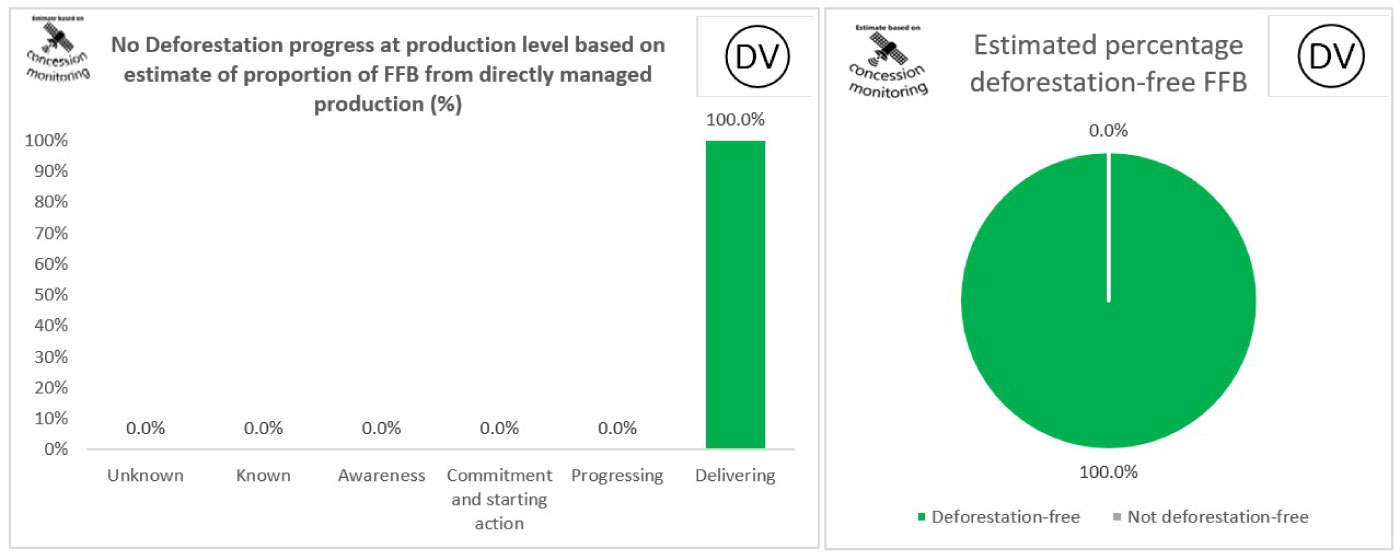

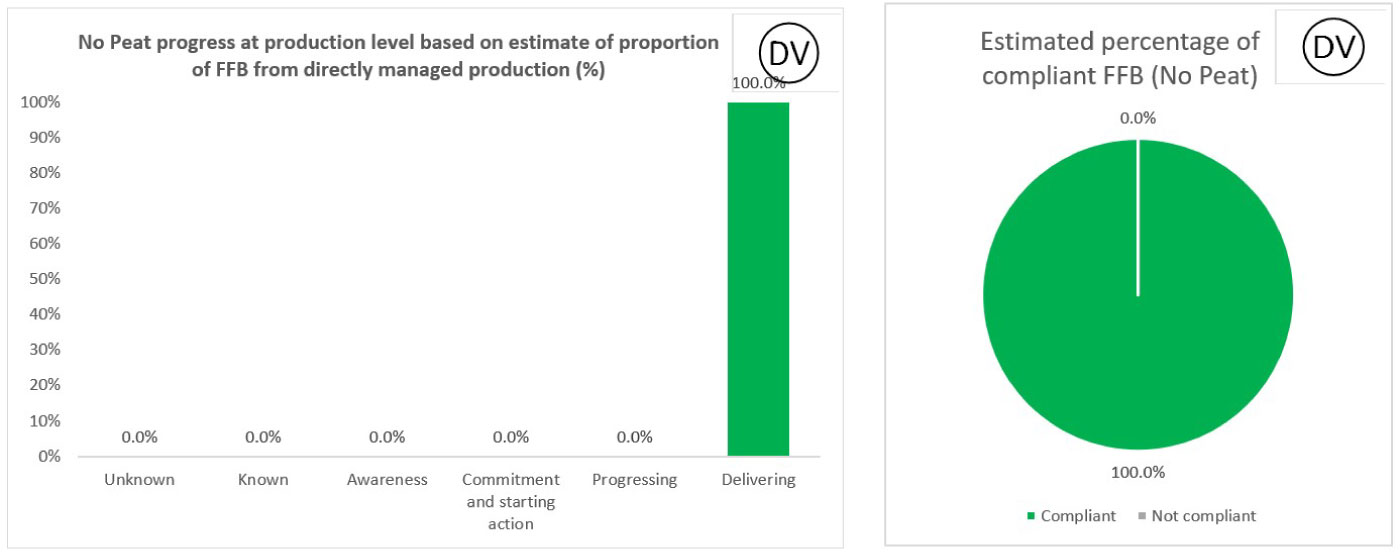

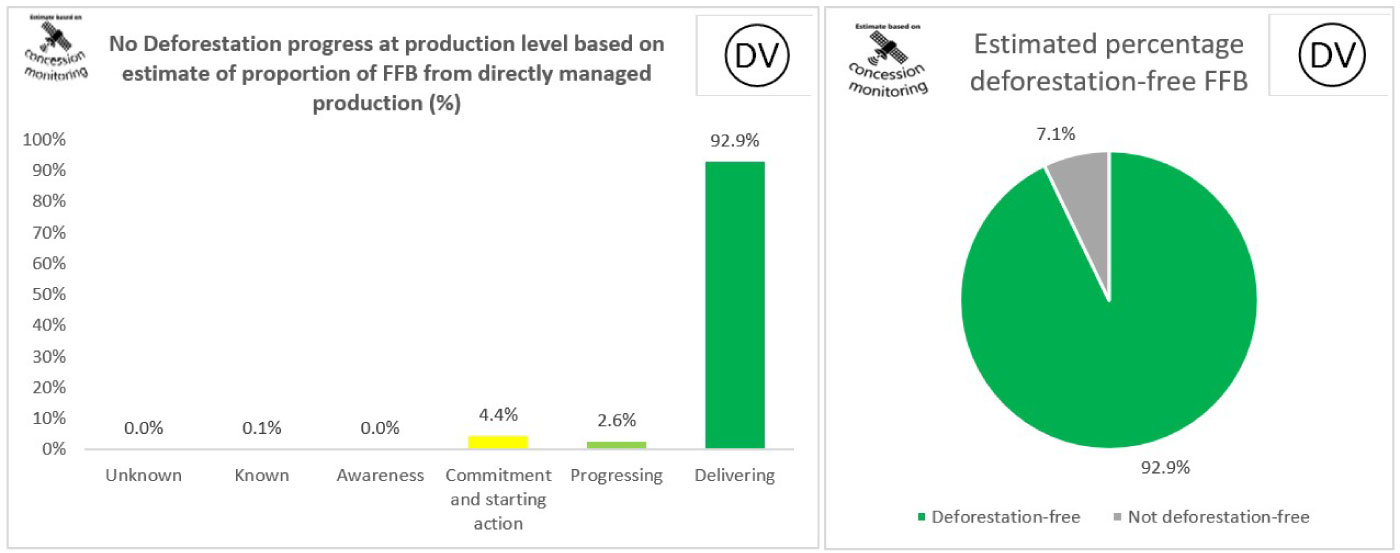

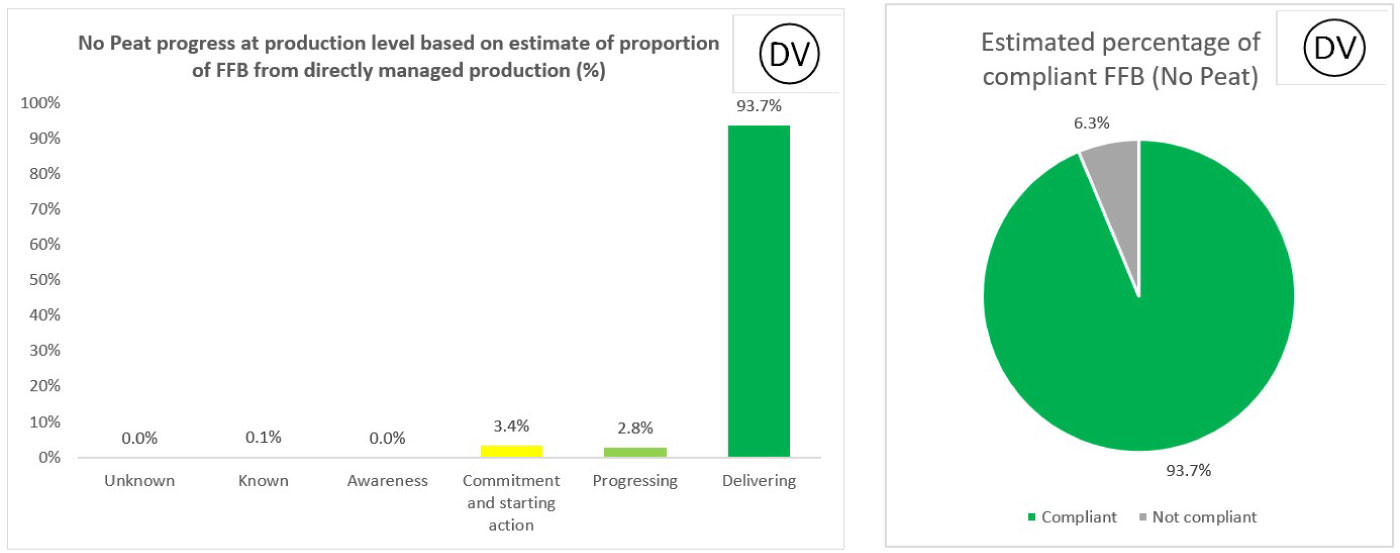

NDPE Implementation Reporting Framework

(NDPE IRF)

Being a member of the Palm Oil Collaboration Group (POCG), ISF utilises the NDPE Implementation Reporting Framework (NDPE IRF) tool to monitor NDPE compliance and commitments of our suppliers in the supply chain. The NDPE IRF tool is utilised by various members of the palm oil sector, including producers, traders, manufacturers, retailers, and other refiners. The tool helps companies to systematically understand and track progress in delivering NDPE commitments in their palm oil supply chains, specifically in identifying gaps and driving improvements for both traceability and transparency.

We monitor the NDPE compliance of our suppliers using the No Deforestation and No Peat profiles towards our aim of achieving zero net deforestation and conversion in our supply chain by 2025. The target is aligned with our chosen definition of "verified deforestation and peat destruction free"(VDF) which includes:

- Concessions are actively monitored with optical and radar satellites for land use changes (GFW Pro, GeoRSPO, and Google Earth)

- No reported land use changes linked to deforestation

- RSPO IP/SG certified volumes sourced from our third-party suppliers and plantations

- Zero environmental legal non-compliance

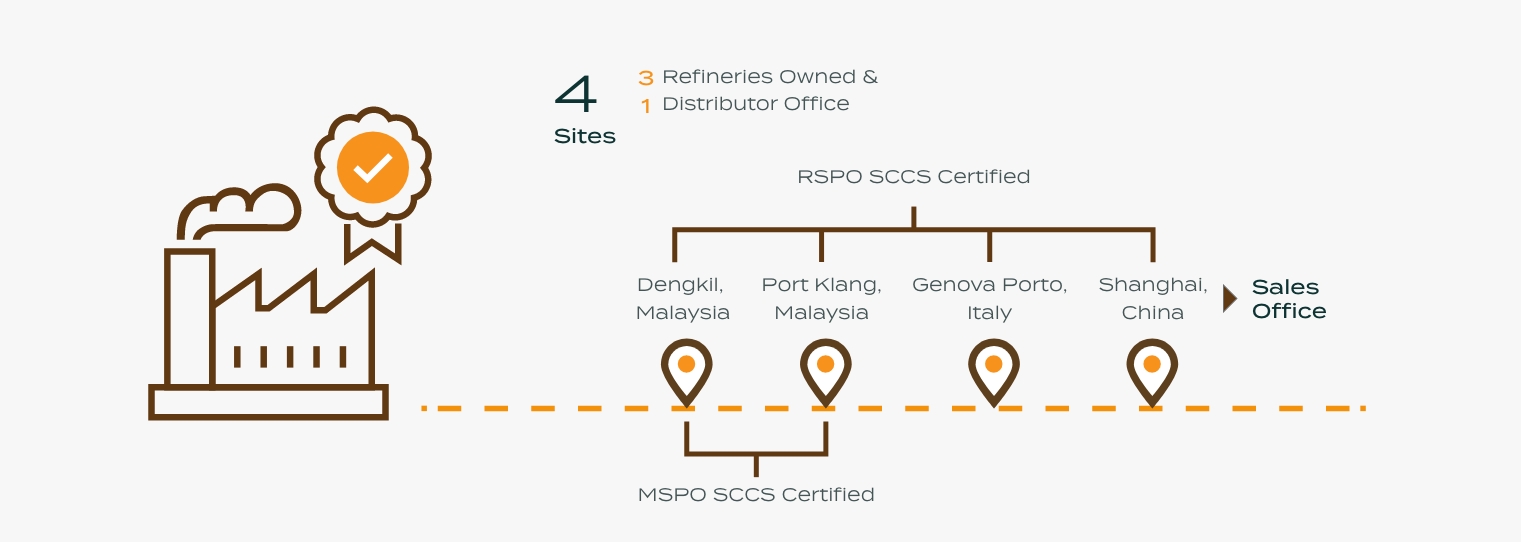

Our NDPE IRF profiles were independently verified by Control Union for our refineries in Malaysia (Port Klang and Dengkil) in June 2025.

ISF’s NDPE IRF Profiles (January – December 2024)

European Union Deforestation Regulations

(EUDR)

ISF is well aware of the upcoming European Union Deforestation Regulation (EUDR), which aims to minimise the consumption of products placed on the EU market that are linked to deforestation or forest degradation. Under the regulation, one of the key traceability requirements is to demonstrate that the raw materials are sourced from land that has not been subject to deforestation after the cut-off date of 31 December 2020.

In line with the EUDR definition of “deforestation-free,” ISF is committed to ensuring that products do not originate from areas where forests have been converted to agricultural use after the specified cut-off date.

ISF is actively working with all stakeholders in our supply chain—including suppliers and customers—to implement the necessary systems and procedures to support full compliance with the EUDR requirements.

Supplier Risk Assessment

100% of our palm suppliers are assessed by our consultant Proforest through the NDPE Implementation Reporting Framework (NDPE IRF) tool, which includes risks on primary forests, peat degradation, protected areas, and fires.